Here at LECO, we have been celebrating Farai-Day (Fri-day) every week for fourteen years! Our new Director of Separation Science Customer Success, Farai Rukunda has been a force of positivity and solutions ever since he accepted his first position as a training specialist. Farai joined host Andrew Storey on LECO's podcast: Measured Science.

Read More…Recent Posts

LECO Australia Latest News (Page 2 of 47)

The thermogravimetric analyses of the TGA801 and its predecessors can do more than measure organic materials. With its ability to handle large, gram-sized samples, the TGA801 has become an invaluable tool for the monitoring of industrial byproducts, such as flue-gas desulfurization (FGD) solids.

Read More…Topics: Thermogravimetric Analysis, TGA801

Both lemons and limes have strong citrus odors, but the difference between these fruits is wide at an analyte level. Identifying these differences is not as easy as it first seems, but the Pegasus® BT and the automated data processing software included in its ChromaTOF® brand software make finding the peaks easy.

Read More…As with all foodstuffs for human consumption, meat is highly regulated. Determining its makeup is essential to confirming a safe product. The faster regulatory analyses can be performed, the quicker you can confirm the quality of your product and maintain production speed.

Determining the moisture content of meat is one such analysis that helps identify the quality and safety of the meat in question. Moisture content can control the texture, taste, and microbial stability of the meat. It also determines the level of retained water, additive solutions for flavoring, and the leanness of meat.

Read More…Topics: Thermogravimetric Analysis, Moisture, Organic, TGM800

Sustainability is on everybody’s mind these days. Companies want to create products that are better for the environment and consume fewer resources. Unilever is no exception. This forward-thinking flavor company has recently been pushing to develop new and delicious plant-based protein substitutes that are more sustainable than meat-based protein but no less healthy (or, preferably, even more healthy!). However, as Unilever scientists Hans-Gerd Janssen and Ed Rosing explain, nature made a pretty delicious protein in the form of meat, with a very distinct flavor and mouth-feel. Creating a substitute isn’t easy.

Read More…The pressure to save money is everywhere these days. The changes due to COVID-19 have only exacerbated the age-old question your own lab has probably asked: how can we cut costs? One hidden expense in a GC-MS lab setting is the cost of cleaning your instrument's ion source.

Read More…A web of factors contributes to a good crop, but the importance of carbon and nitrogen cannot be overstated. From soil to fertilizer to the plant matter itself, the mix of carbon and nitrogen play key roles in the development and growth of the plant. Knowing the carbon and nitrogen levels in every aspect of your field can help you maintain quality control over the end result.

Read More…Microplastics are a ubiquitous presence in the world, found from Arctic snow to Antarctic ice and everywhere in between. There are trillions of microplastic particles floating on surface water, and everyone from infants to adults are presumed to be ingesting anywhere from dozens to tens of thousands of these particles every day. But the science of microplastics, especially the incredibly tiny, potentially-cell-disrupting nanoplastics, is only just beginning. The effects of these microplastics isn't well known, largely because the scale of microplastics isn't well known. They are, by definition, difficult to see.

Unless you're looking in a second dimension.

Read More…Having an abrasive cut-off wheel break in the middle of a cut is scary and can happen even on the best equipment. Replacing the broken blade interferes with your material lab’s smooth workflow. If your sectioning blades are breaking frequently, you might be experiencing some common failures. Below, we outline five of the most frequent causes of a broken blade and how to fix them.

Read More…

Topics: MET Tips, Sectioning

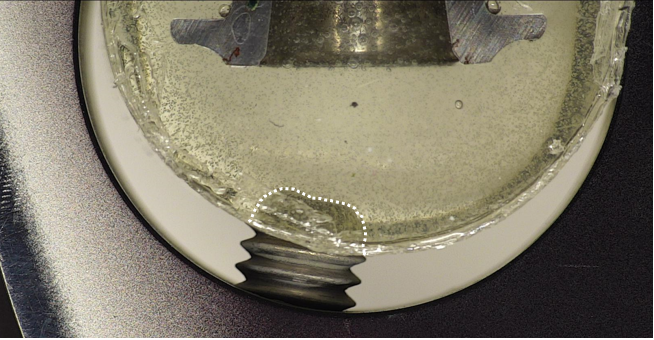

Have you ever let long-cure epoxy mounts cure overnight, only for the setscrew to push into the mount when you went to load it into your grinder/polisher’s fixed specimen holder? When the epoxy is soft, the specimen isn’t secure in the mount or in the specimen holder, and proper grinding and polishing becomes impossible. The eight hour cure time for long cure epoxy means you can’t just whip up a new one; if something goes wrong, you’ve effectively lost an entire day as the replacement also needs eight hours to cure.

But if you left your mounts to cure overnight, shouldn’t that have been more than enough time? What could have gone wrong?

Read More…