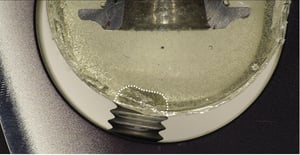

Have you ever let long-cure epoxy mounts cure overnight, only for the setscrew to push into the mount when you went to load it into your grinder/polisher’s fixed specimen holder? When the epoxy is soft, the specimen isn’t secure in the mount or in the specimen holder, and proper grinding and polishing becomes impossible. The eight hour cure time for long cure epoxy means you can’t just whip up a new one; if something goes wrong, you’ve effectively lost an entire day as the replacement also needs eight hours to cure.

Have you ever let long-cure epoxy mounts cure overnight, only for the setscrew to push into the mount when you went to load it into your grinder/polisher’s fixed specimen holder? When the epoxy is soft, the specimen isn’t secure in the mount or in the specimen holder, and proper grinding and polishing becomes impossible. The eight hour cure time for long cure epoxy means you can’t just whip up a new one; if something goes wrong, you’ve effectively lost an entire day as the replacement also needs eight hours to cure.

But if you left your mounts to cure overnight, shouldn’t that have been more than enough time? What could have gone wrong?

When using long-cure epoxy for mounts, it's important to remember these five things:

- Curing of Epoxy is Sensitive to the “Recipe”

Using the proper ratio of resin to hardener is of the utmost importance. When small batches are prepared, it can be quite difficult to properly measure the components by volume. In such cases, measuring by weight is the only way to assure a proper ratio. - Contaminated Specimens Can Cause Problems

Specimen surface contaminants can interfere with the chemical reactions taking place when epoxy cures. Contamination may be related to the sectioning machine coolant, or from other sources. In any case, it should be removed prior to mounting. Many contaminants can be removed with a water rinse, followed by rinsing with ethanol. Others may require more aggressive treatments. - Adequate Mixing Is Important

Mixing for too short a time can result in different locations in the mixture having different hardener/resin ratios. This can result in “soft spots” and/or a poorly cured mount. Epoxy mounting materials have fairly long working times. This means there is plenty of time for proper mixing of the two components. Two minutes of slow and steady stirring is recommended. - Cold Slows Things Down

The curing of epoxy is an exothermic reaction; meaning that it generates heat. If the specimen or the epoxy components are very cold, the curing progress will be slowed. If at all possible, everything involved in the mounting process should be at room temperature when it is started. - Use Only High Quality Epoxy

Outdated or otherwise compromised epoxy resin or hardener may not react properly after mixing and may not fully cure. Make sure to store the epoxy components, tightly sealed, in a cool, dark, dry place. Be extra careful using epoxy that is beyond its “best of used by” date.

Taking extra care in your preparation can prevent losing hours to remaking mounts. If you are still having trouble with your epoxy not curing properly even after taking into account the precautions listed above, let us know. Contact us at met_tips@leco.com, and we will have an expert reach out to help you get your lab running smoothly once again.