Our innovative analytical instrumentation provides users with solutions for a wide range of applications. We want to help your lab succeed, which is why we share examples of the processes, methods of analysis, and results our instruments can obtain in the form of application notes. We want our current and potential customers to feel at ease with our instrumentation in the lab, and our application notes highlight the right instrument for each specific application.

Below you’ll find the latest application notes for our TGA801 and TGM800, both of which use an automated thermogravimetric technique to streamline the determination of moisture, volatile content, ash, and LOI respectively (TGA: moisture, ash, VC, LOI; TGM: moisture). The automated thermogravimetric instrument replaces the slow, often labor-intensive, manual methods. This not only eliminates the frustration you feel when manually weighing and transferring samples between ovens and desiccators, but the automation features also help to eliminate the potential for errors. Key features of each instrument include:

|

TGA801

|

|

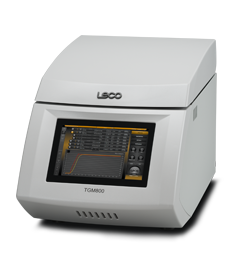

TGM800

|

|

LOI in Combustion Residues

Thermogravimetric analysis (TGA) is commonly used to determine selected characteristics of materials that exhibit either mass loss or mass gain due to decomposition, oxidation, or loss of volatile materials such as moisture. Macro TGA systems using gram-size samples allow more accurate mass measurements for characterization of heterogeneous materials. Loss on Ignition (LOI) in combustion residues refers to the mass loss when heated in an air or oxygen atmosphere to a high temperature. In the cement industry, the term LOI refers to a mass loss in a sample heated to 950 oC. LOI values in combustion residue values are used by industries that utilize combustion residues in various processes and products, such as the production of cement, providing a quality parameter.

Moisture and Ash Determination in Animal Feed

An accurate determination of moisture and ash content in flour products provides important information related to the food quality and safety (texture, taste, microbial stability). Moisture is also a key variable used to calculate a products purity, yield, and/or resulting constituent analysis on a dry basis. Ash content is also an indicator of contaminants such as bran in refined flours. The LECO TGA801 is a macro thermogravimetric analyzer that allows up to 19 samples to be analyzed simultaneously.

Determination of Total Solids in Milk

The TGM800 is a thermogravimetric analyzer designed to directly determine moisture content of materials using a loss-on-drying technique. Mass loss of the sample is measured as a function of the oven temperature by controlling the atmosphere and ventilation rate. An accurate determination of moisture content in milk products provides important information related to the food quality and safety (texture, taste, microbial stability). Moisture is also a key variable used to calculate a products purity, yield, and/or resulting constituent analysis on a dry basis.

Determination of Moisture in Cheese

The TGM800 is a thermogravimetric analyzer designed to directly determine moisture content of materials using a loss-on-drying technique. Mass loss of the sample is measured as a function of the oven temperature by controlling the atmosphere and ventilation rate. An accurate determination of moisture content in cheese provides important information related to the food quality and safety (texture, taste, microbial stability) as well as a key variable used to calculate a products purity, yield, and/or resulting constituent analysis on a dry basis.