When the Kaunis Iron Mine opened in Sweden, it was the newest in one of Sweden's biggest industries. The mine contracted with Degerfors Laboratory (D-LAB) for their iron analysis. Before analysis could be run on the samples, however, the ore had to be dried and moisture levels measured. D-LAB had a problem: their current moisture determination methods used a manual balance that could only handle one sample at a time, requiring a technician's attention every five minutes. The ISO 3087:2020 method used was also a problem, as a single run could take more than 5 hours to complete. The lab turned to LECO for a solution.

When the Kaunis Iron Mine opened in Sweden, it was the newest in one of Sweden's biggest industries. The mine contracted with Degerfors Laboratory (D-LAB) for their iron analysis. Before analysis could be run on the samples, however, the ore had to be dried and moisture levels measured. D-LAB had a problem: their current moisture determination methods used a manual balance that could only handle one sample at a time, requiring a technician's attention every five minutes. The ISO 3087:2020 method used was also a problem, as a single run could take more than 5 hours to complete. The lab turned to LECO for a solution.

LECO's TGM800 system is a thermogravimetric analyzer for the determination of moisture content using a mass-loss-on-drying technique. Mass loss of the sample is measured as a function of the oven temperature and the drying time. Up to 16 samples can be analyzed simultaneously in one run. By the numbers alone, this instrument would already be an improvement over the manual moisture balance if it could deliver on its promise.

LECO's TGM800 system is a thermogravimetric analyzer for the determination of moisture content using a mass-loss-on-drying technique. Mass loss of the sample is measured as a function of the oven temperature and the drying time. Up to 16 samples can be analyzed simultaneously in one run. By the numbers alone, this instrument would already be an improvement over the manual moisture balance if it could deliver on its promise.

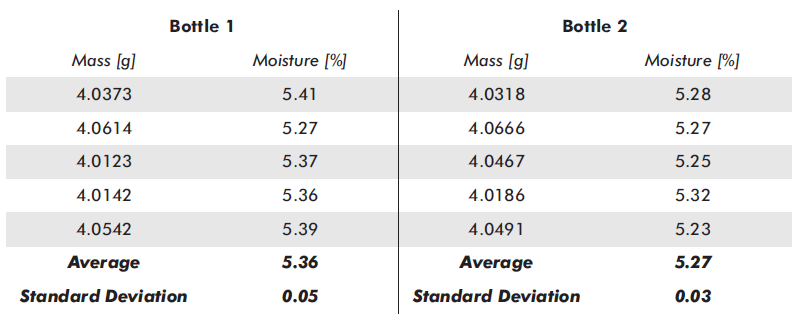

To test the TGM800, D-LAB sent iron ore samples to LECO's own labs in St. Joseph, Michigan, and Berlin, Germany. The two bottles of iron ore samples were run through the TGM800 as both 1 g and 4 g samples, with the results compared.

The results were consistent between both the first and second bottles and between the 1 g and 4 g samples, and the results and standard deviation obtained by the TGM800 matched the results obtained using the manual moisture balance. However, the TGM800 was able to analyze 16 samples simultaneously in runs that took between 20 and 25 minutes, including the sample preparation time.

Consistently obtaining the same level of results with a 16x sample throughput in a fraction of the original time was an easy choice for D-LAB, and they went ahead with the purchase of a TGM800. Now, the TGM800 handles 30,000 samples a year, with D-LAB considering purchasing a second instrument as their analysis demand continues to increase. D-LAB does still have their manual moisture balance to use as a backup, but with 100% uptime on the TGM800, they have never had to use it.

LECO is pleased with the huge success of the TGM800 at D-LAB and is looking forward to continuing working with them in the years to come. To read more about the process D-LAB used to verify the TGM800's results, access the white paper here.